Termostop

Preparation for the application of thermo-liquid insulation ThermoStop

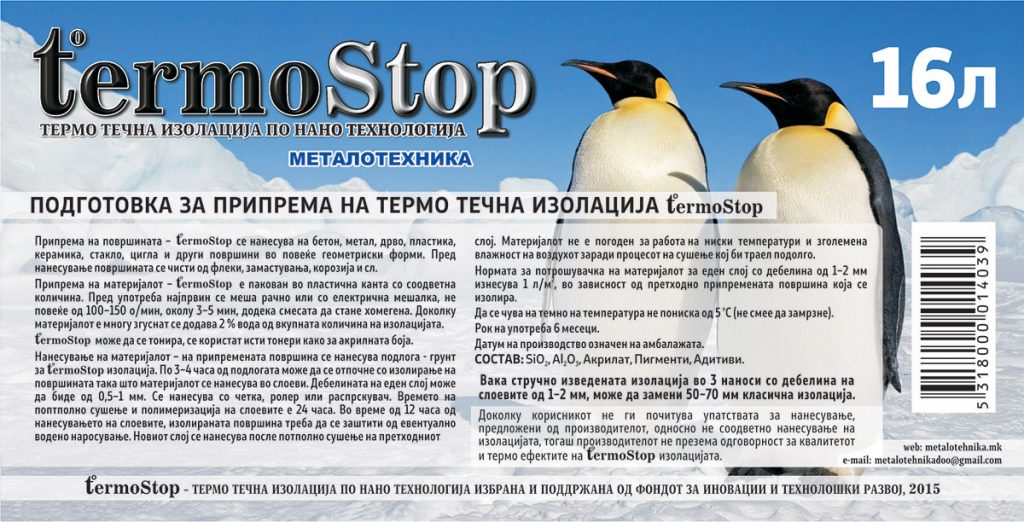

Surface Preparation

“ThermoStop” insulation is applied to metal, concrete, brick, wood, glass, ceramics, plastic, rubber, cardboard, and almost all other industrial and construction materials and substrates. The surface on which this material is applied should be clean, degreased and free from corrosion. The application is possible on surfaces whose temperature can be in the interval +5 to +150 oC.

Cleaning the surface means that there is no dust, dirty surfaces, stains, grease, corrosion, etc. If the surface is greasy, clean it with suitable standard detergents or other chemical agents. When applying the material, the surface should be washed and dried. If corrosion is removed, it is done in the usual way by painting.

Preparation of the material

The factory packaging is opened. The material is packed in plastic bins of 3, 5 and 16 liters.

Mix with an electric paint mixer, no more than 100 – 150 rpm and no more than 5 min. until the content becomes homogenous with a paste-like consistency.

If the material is very thick (for example after standing for a long time), 50-120 ml of water can be added to one bucket of 16 l of material. It is desirable to drain the material through a filter, to ensure specific and good application with “airless” sprayers.

Application of the Material

To tint the “ThermoStop” material, the same toners can be used as for acrylic paints (do not add more than 1% pigment). Tinting does not lose the properties and characteristics of the material, and gives the possibility of choosing a color for an aesthetic and technological appearance.

The material is applied in layers. The thickness of one layer can be from 0.3 mm to 0.5 mm. The material can be applied using an airless sprayer under a pressure of 40 to 100 bar with a nozzle of 0.5 mm. The material can also be applied with a regular brush or roller. This method is not recommended for professional activities, but it is suitable for repairs of damaged insulation materials as well as for application in apartments or smaller areas. Brushing is done in the same way as acrylic paint. The time of complete drying and polymerization of the layers is 24 hours. Within 12 hours of the application of the layers, protection against possible water precipitation should be ensured. The new layer is applied after complete drying of the previous layer.

At low temperatures and in conditions of increased air humidity, the drying process takes longer.

The consumption rate of the material is 1 liter per 1 m2, depending on the previously prepared surface for insulation.

* This expertly performed insulation in 3 layers with a thickness of 2 mm replaces approximately up to 50 mm of classic insulation.

If the user does not follow the application instructions suggested by the manufacturer, i.e. not properly applying the insulation, then the manufacturer does not assume responsibility for the thermal effects of termoStop insulation.